Tresca Engenharia is one of the pioneering companies in Brazil specializing in the use of stress analysis using the finite element method to check the integrity of industrial equipment, increase the service life, study reinforcements and, in the manufacturing phase, optimize design with thickness, weight and material reductions (“design by analysis”).

USE

Any material or component can be analyzed, as long as its mechanical property (modulus of elasticity) is known. TRESCA already analyzed components made of steel and other metals, fiberglass reinforced plastic, polymers, rubber, cast iron and wood.

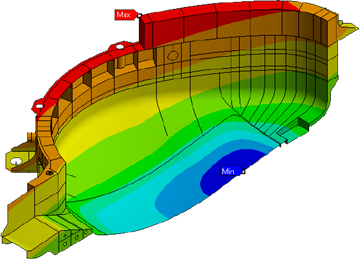

The method is applicable in calculation of stress, deformation, temperature distribution, thermal stress and vibration; dynamic response to random, seismic or harmonic excitation and plastic deformation by plasticity or creep.

In some cases, a non-linear analysis is made in order to study the deformation effect on the structure response and buckling analysis (elastic instability)

The stresses found are then compared, according to the case, with the allowable stresses, or the remaining life in fatigue or creep is calculated.

With the stresses found in the finite element analysis, a remaining life calculation or the limit operating condition of the component can be calculated. If the analysis is made during the design, is possible to optimize it, reducing its cost and increasing the operating capacity and remaining life.

If the product is moulded, it is possible to save on the mould cost and experimental samples. The analysis also replaces resistance and durability tests.

Before repairing, assess the criticality of the cracks!

During maintenance inspections on equipment and industrial plants, after carrying out ultrasonic, TOFD, eddy current, ACFM or phased array tests, it is necessary to carry out a criticality assessment of cracks or flaws.

The repair of flaws and cracks has disadvantages (such as the introduction of stresses due to welding) and should only be carried out as a last resort. In most cases, cracks can be approved using API 579 / ASME FFS-1 / BS 7910 criteria.

In 1994, Tresca Engenharia developed the SafeCrack software, based on the criteria of API579 / ASME FFS-1 and BS 7910. And since then it has carried out the assessment of thousands of cracks and flaws and the calculation of the remaining useful life for mechanical damage processes.

Tresca Engenharia also assesses thickness reduction, deformations and other non-conformities found in the inspection of equipment.

The fracture calculation and the calculation of other damage phenomena such as localized corrosion, creep and fatigue is carried out according to the English Standard BS 7910 or the American Standard API 579.

Reliability, Integrity and Security!

Combining the best engineering tools, including numerical simulation methods using the finite element method and extensive knowledge of engineering standards and codes, with field data collected using non-destructive testing techniques and the long experience of its professionals, Tresca Engenharia always works in the direction of presenting optimal solutions to its clients, guiding future inspections, increasing the reliability, integrity and safety of equipment and installations.

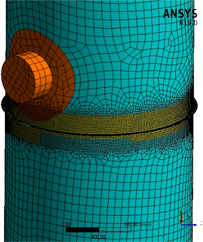

Combining fluid-dynamic analysis with mechanical simulations, Tresca Engenharia elaborates a complete work, proposing optimal solutions both from the point of view of mechanical integrity, as well as the optimization of the design and operation of the equipment, as a whole.

Tresca Engenharia performs fluid – dynamic analysis and analysis of fluid-structure interaction with the ANSYS AIM program, where it is possible to determine:

Laminar and turbulent flow

Compressible and incompressible flow

Fluid speed profile

Vortex and turbulence regions

Cargo loss

Fluid flow

Fluid pressure

Thermal exchange between fluid and structure

Residence time of a particulate material

For fluids under permanent and single-phase conditions.

Some examples of performance: ducts and transitions, exchangers, heaters, dryers, coolers, etc.